Technology

Innovative Pyrolysis Technology with 20+ Years of Development

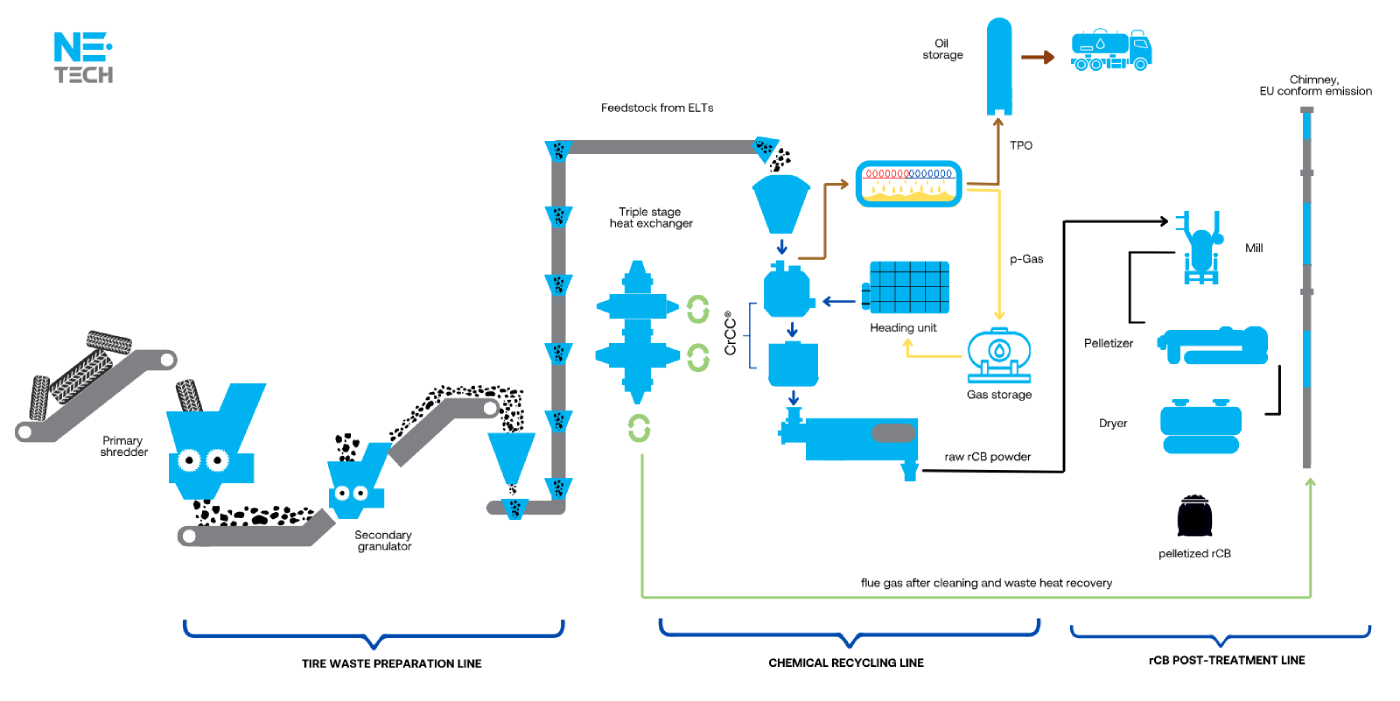

Our pyrolysis technology for tire recycling has been continuously refined for more than 20 years and is protected by an international patent. The complete pyrolysis reactor system has now advanced to its 7th generation, known as the Continuous Revolving Charge Cycle (NE-TECH CrCC®) system.

This technology uniquely combines the principles of classical batch-type reactors with continuous auger-type feeding, achieving an outstanding energy balance and producing high-quality output materials.

The process operates in a fully enclosed system, entirely PLC-controlled and ready for automated operation. With its modular design, each module has a capacity of 10,000 metric tons per year and is delivered with two main reactors.

Advantages of NE-TECH’s CrCC® Technology

- CO2 reduction: 14.000 Mt/module/year

- Energy Efficiency:

- Eliminates the use of fossil fuels for heating by utilizing purified pyro-gas fractions to power the reactors

- Employs waste heat recovery through a triple-stage heat exchanger

- Utilizes gravity for the internal transfer of solid and liquid materials

- Modular Design:

- Pre-assembled at our site, significantly reducing onsite installation time and costs at the investor’s facility

- Simplifies installation processes

- Allows for future capacity expansion

-

Enhances flexibility in maintenance

- Built within 40-foot steel frame systems

- EU-Compliant Emissions

- Recovered Raw Materials for Industry:

- TPO

- rCB

- Steel

CrCC® modul parameters

- Capacity: 10,000 Mt/year ELT

- Feedstock Input: 800–1,200 kg/hour (prepared feedstock)

- System Heating: Powered by the produced and purified process gas

- Heating Mode: Continuous

- Feeding and Discharging: Batch type

- Daily Recycling Throughput: 24 Mt feedstock / day

- TPO production: 4,000 Mt/year

- rCB production: 3,200 Mt/year

- Installed Electrical Power: 395 kW (average operational consumption: 210 kW)