Turning Tires

into Tomorrow

Sustainable and Profitable Tire Recycling Solution

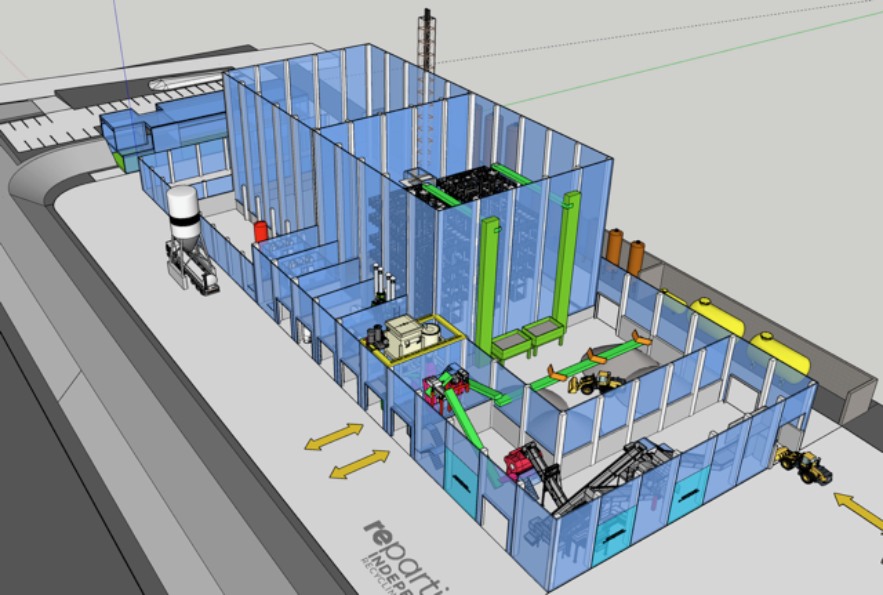

We offer environmentally friendly yet profitable technology that provides a practical solution for managing tire waste. Through our advanced tire pyrolysis process, we recover valuable secondary raw materials—such as REACH-certified pyrolysis oil, recovered carbon black (rCB), and steel—which can be reintegrated into the industrial material cycle.

Every component of our technology has been thoroughly tested in an industrial, operational environment. The process runs within a closed, fully PLC-controlled system, designed for seamless automated operation. All facilities we deliver are provided as turnkey solutions.

Our team has the expertise to install complete pyrolysis facilities, including storage systems, full tire-shredding lines, pyrolysis technology, and rCB post-treatment units. Additionally, our engineers support local EPC contractors and construction companies throughout project preparation, operation, and staff training.

About us

We develop, manufacture, and deliver innovative tire pyrolysis technology as fully operational systems.

Sustainability

Our goal is to reduce environmental impact by developing technology that produces recyclable secondary raw materials on an industrial scale – thereby contributing to a more livable and sustainable world.

Recycling plants with technology of NE-TECH

Dunaharaszti - Hungary

since 2005

Karcag - Hungary

operation from Jan 2026

Feluy - Belgium

Ongoing

Shaping the Future Through Technology

For more than 20 years, our pyrolysis technology for rubber recycling has been continuously developed and refined. An international patent protects the system and has now reached its 7th generation of pyrolysis reactor systems.

NE-TECH’s CrCC® technology is a unique hybrid solution that combines the advantages of classical batch-type reactors with continuous auger-type feeding systems. This innovative design ensures an excellent energy balance while delivering high-quality output materials.

The entire process takes place in a closed, fully automated system. Thanks to its modular design, the technology can be adapted flexibly to different project scales and customer needs.

Contact

NE-TECH HQ

- H-1238 Budapest Grassalkovich road 40.

- info@ne-tech.eu